|

| |

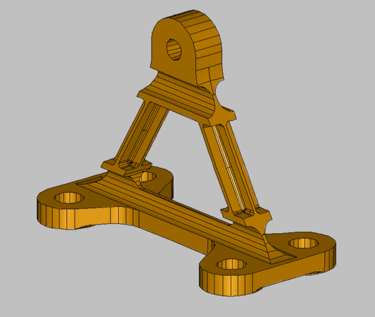

From Idea to Part: The Story of an A-Frame SupportDue to the thermal requirements of one particular project and the necessity for a light but stiff mounting, it was decided to use an A frame but adapt it to simulate a blade mount. This provides a flexible support, which can comply with the stress due to thermal contraction while being incredibly stiff. This was designed and modelled to give a strong support with reduced mass and minimal thermal conductance.

3-D Model of Support

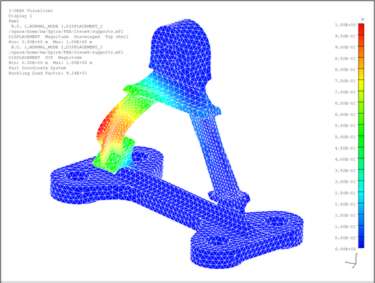

The model was then meshed and prepared for Finite Element Analysis. Finite element techniques used at MSSL cover linear and non-linear static and dynamic analysis. The advantages of using MSSL are:

Fine Volume Mesh for Buckling Analysis

The results are presented in a professional graphical format with comprehensive conclusions. The ones shown here are the first buckling mode and show a typical first order collapse, sufficiently above the required strength.

This was confirmed by MRE - outdoors test, the results of which are shown here.

The mount under went extensive thermal conductance testing which was performed in-house. A heater was placed at the top of the mount and the conductance was measured. From these results the heat flux at 4K was calculated.

The finished mount, made by Electromec.

This page last modified 18 September, 2007 by Martin de la Nougerede |